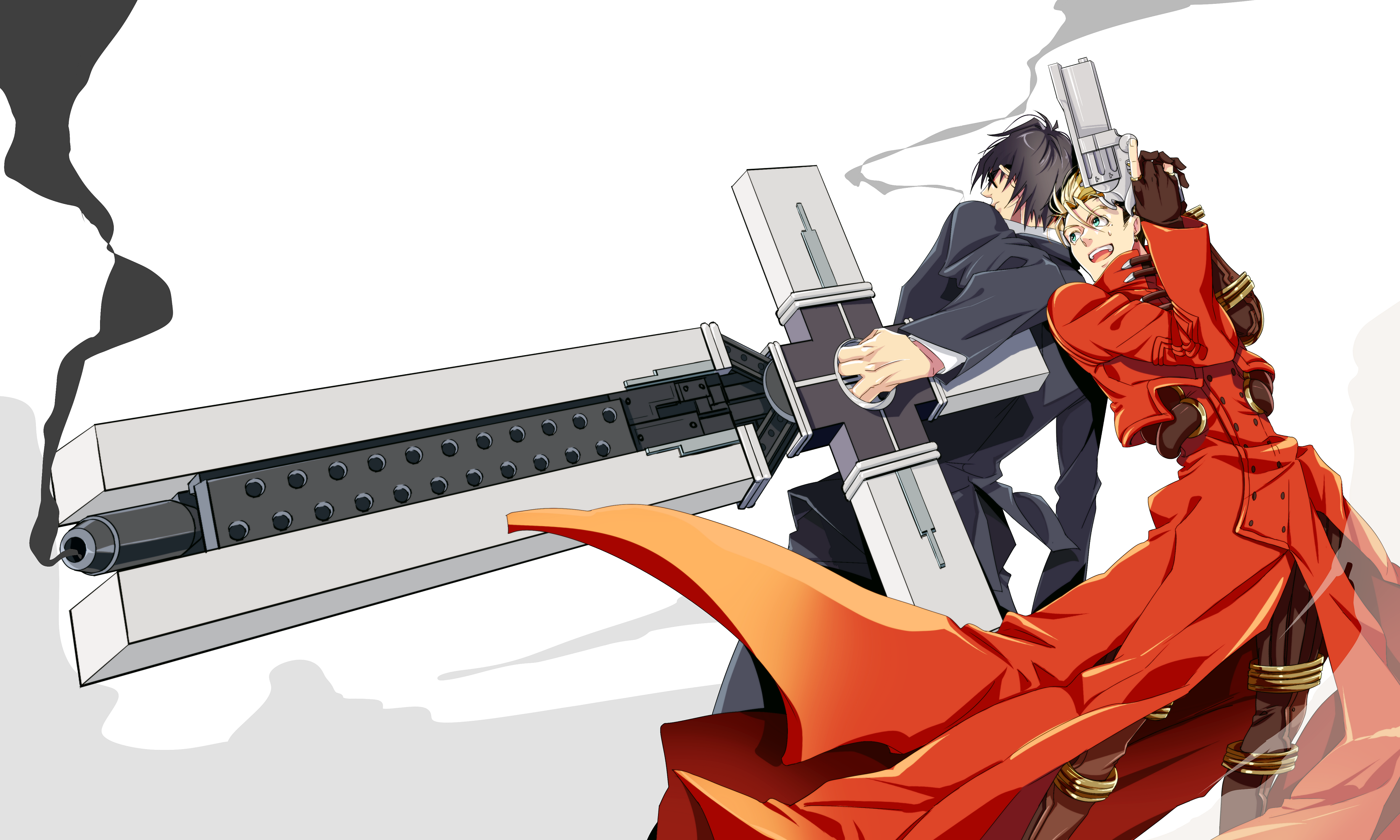

Help a child learn to organize and store his game cartridges in a

convenient hanging custom game organizer.

Our sample custom game organizer fits over a hanger and

contains 12 separate pockets: eight small pockets

for hand-held or other game cartridges and four

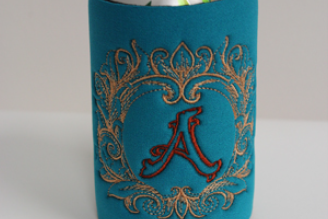

large pockets for DVD games. Customize the pocket

size and number to meet individual needs. While the

sample holder has boy-inspired motifs, it can easily

be adapted for a girl by choosing feminine motifs.

Supplies

• 1 yard of 60″-wide denim

• 1⁄ 2 yard of 45″-wide plaid fabric for binding

• Mesh stabilizer

• Embroidery, bobbin and sewing thread

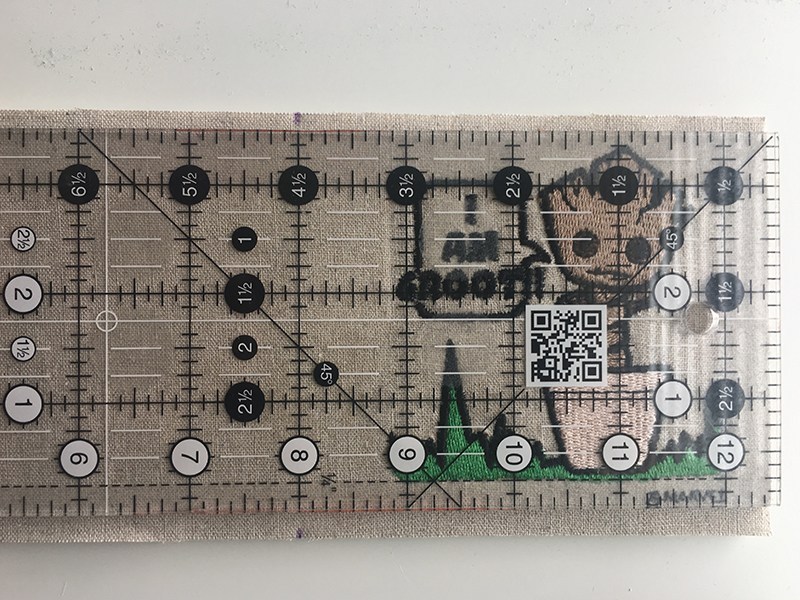

• Rotary cutter, mat and clear ruler

• One sturdy hanger measuring 14 1⁄ 2″ across at base

• Air-soluble marker or tailor’s chalk

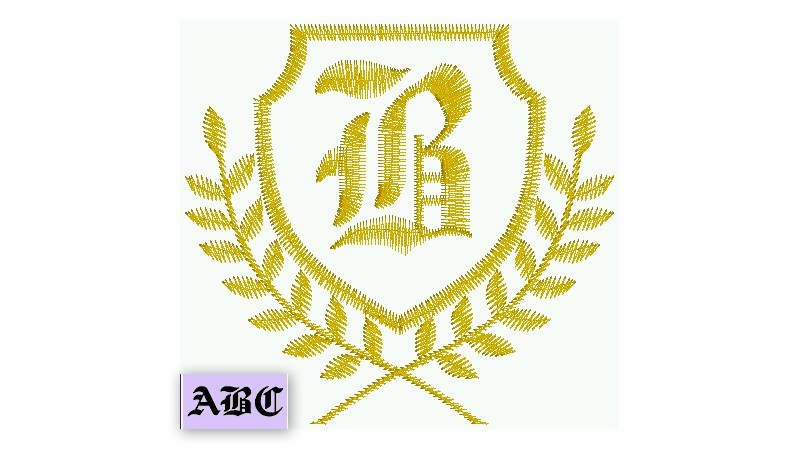

• Designs of your choice no larger than 2″ x 3 3⁄ 4″

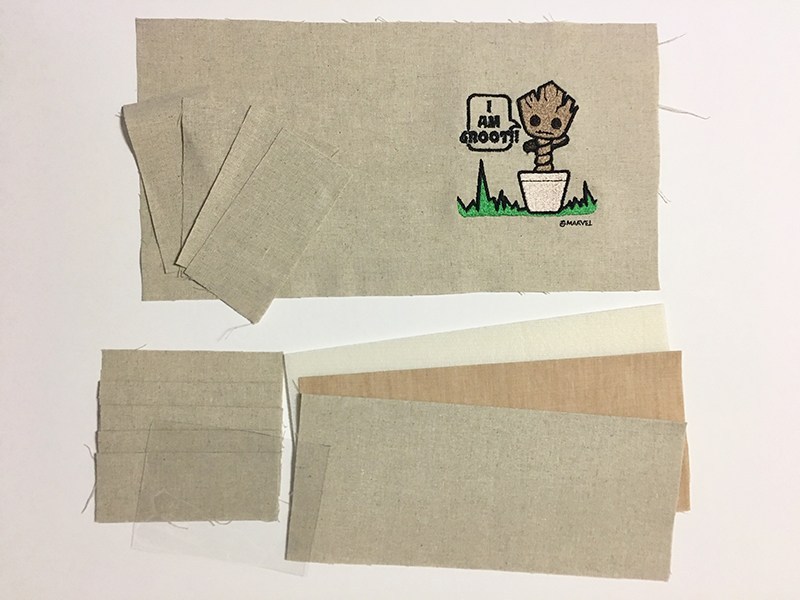

Cutting

Note: For accuracy, cut pieces with a rotary cutter

and clear ruler.

• Cut two 16″ x 30 1⁄ 2″ rectangles from denim.

• Cut eight 4″ x 5″ rectangles from denim.

• Cut four 5 1⁄ 4″ x 9″ rectangles from denim.

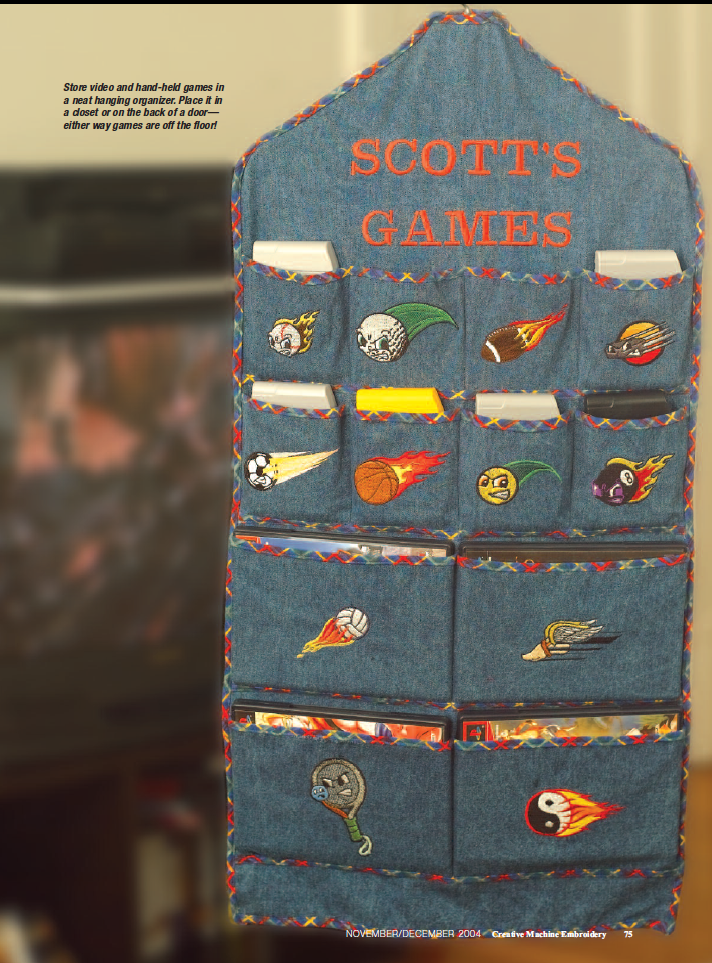

• Shape the top of the organizer to fit your hanger

by following the diagram in figure (A).

• Cut approximately 7 yards of 1 1⁄ 4″-wide bias strips

from the plaid fabric for the binding.

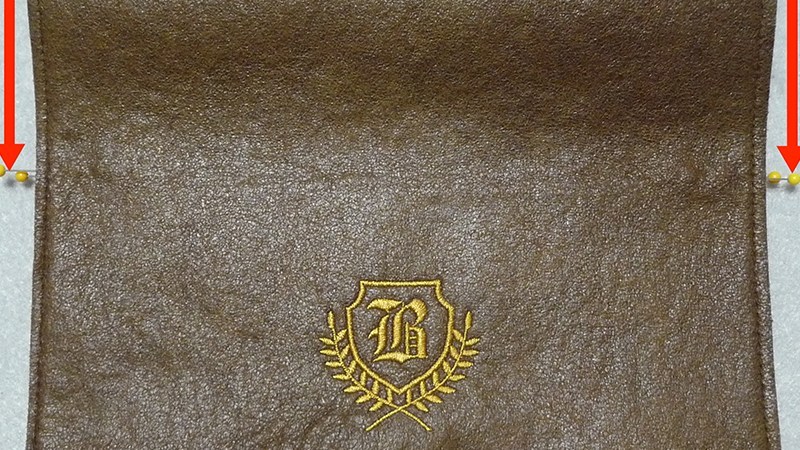

Embroidery

• Mark the center point on each 4″ x 5″ and

5 1⁄ 4″ x 9″ denim rectangles.

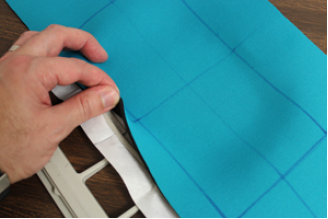

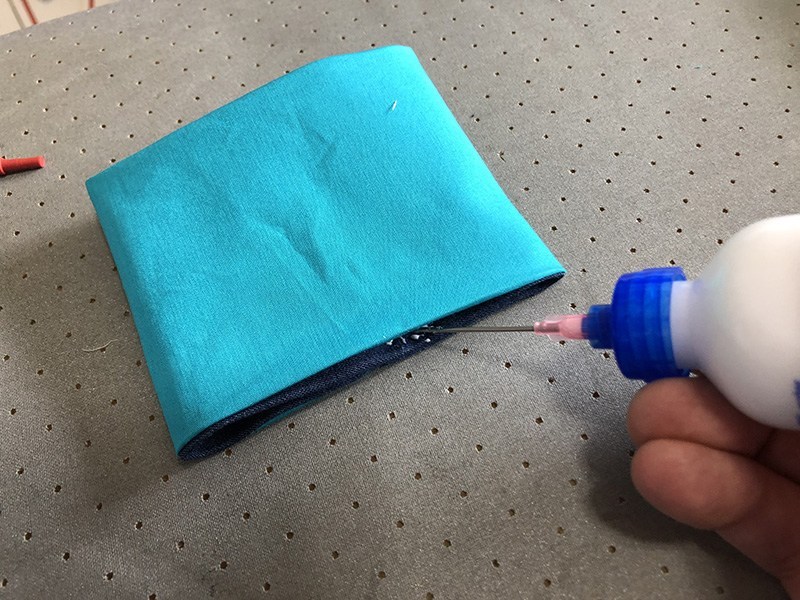

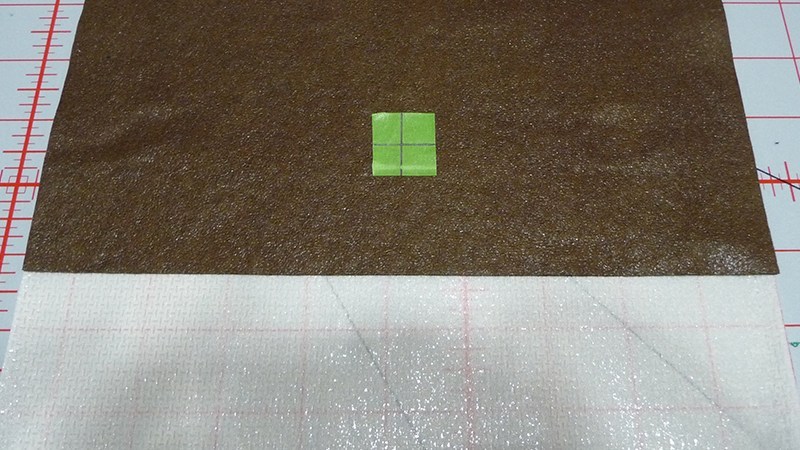

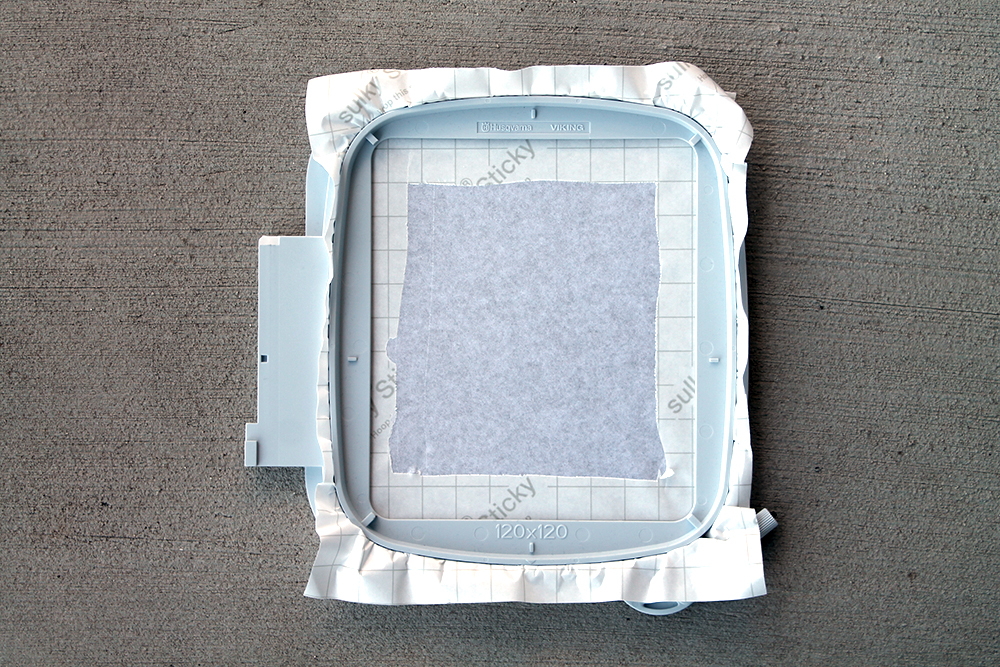

• Hoop the mesh stabilizer, place it in a box for

protection and spray the stabilizer with temporary

adhesive. Note: If a dense design with a high stitch

count is used, two layers of mesh stabilizer may be

necessary; test-stitch designs first on scrap fabric for

best results.

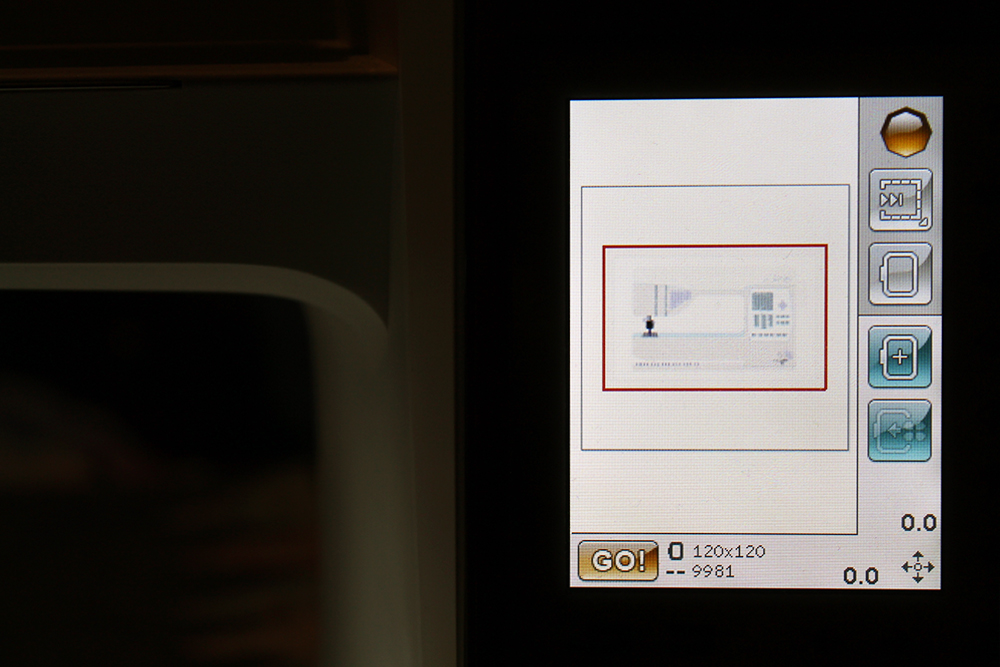

• Secure a denim rectangle onto the stabilizer;

aligning the mark with the hoop center. Embroider

the design of your choice.

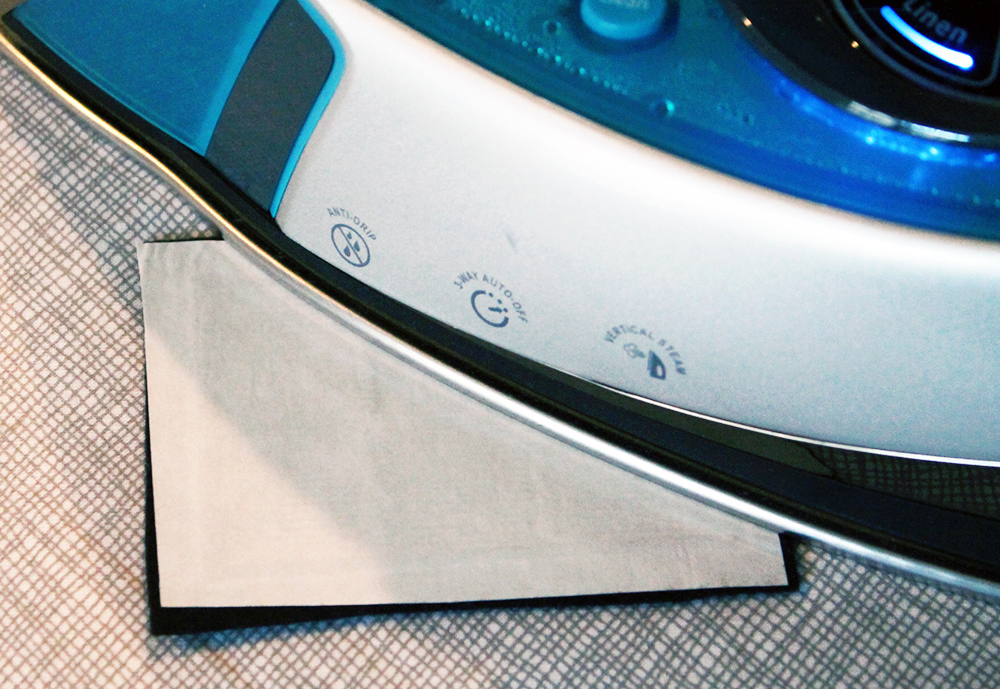

• Remove the hoop from the machine,

remove the fabric from the hoop and cut away

the stabilizer. Press each design on the fabric

wrong side with steam and a press cloth.

• Repeat for each 4″ x 5″ and 5 1⁄ 4″ x 9″

denim rectangle.

• Embroider a name at the hanger upper

edge to personalize the organizer using the

lettering or software desired.

Construction

• With the embroidered motif facing up,

shape each 4″ x 5″ and 5 1⁄ 4″ x 9″ denim

rectangle by marking and tapering each piece

as shown (B).

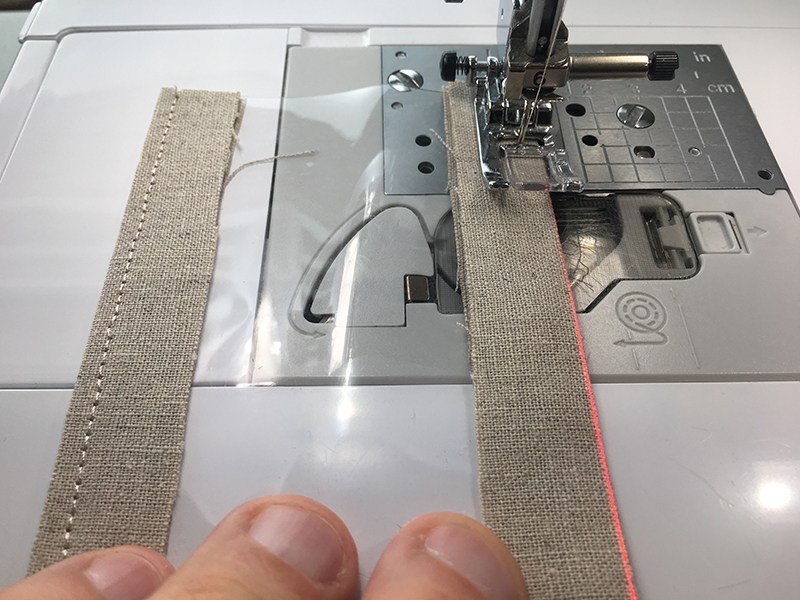

• Finish the side edges with a serger or a

zigzag stitch.

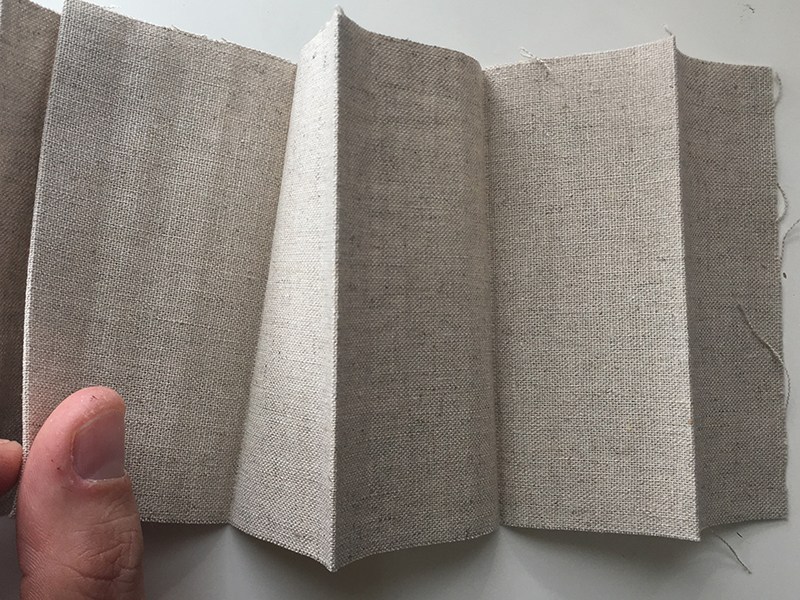

• Arrange the shaped motifs as desired, creating

two rows of small rectangles and two rows

of larger rectangles.

• Sew the rectangles together. Press seams

open.

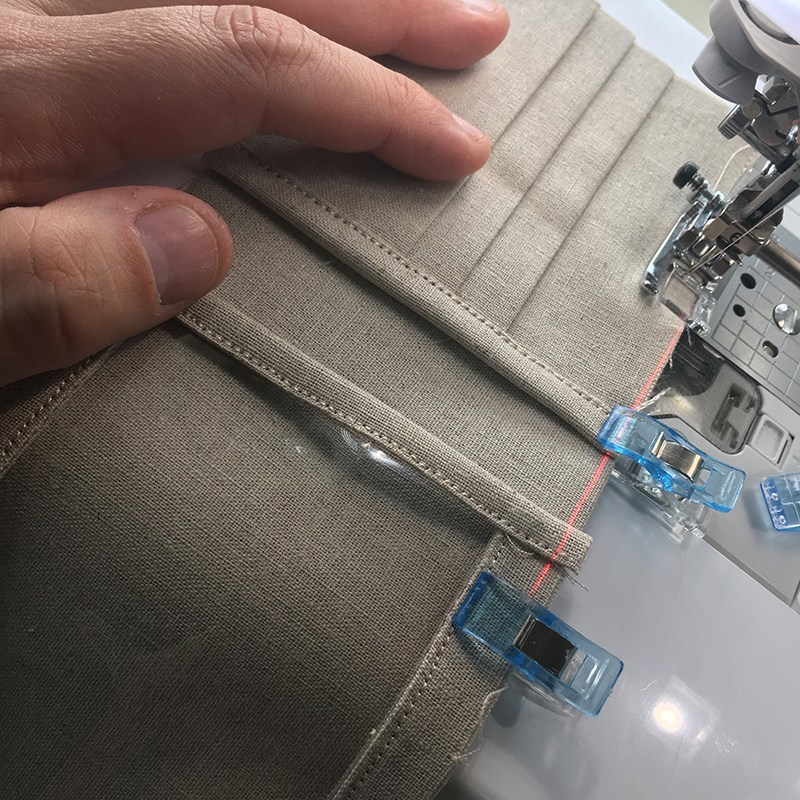

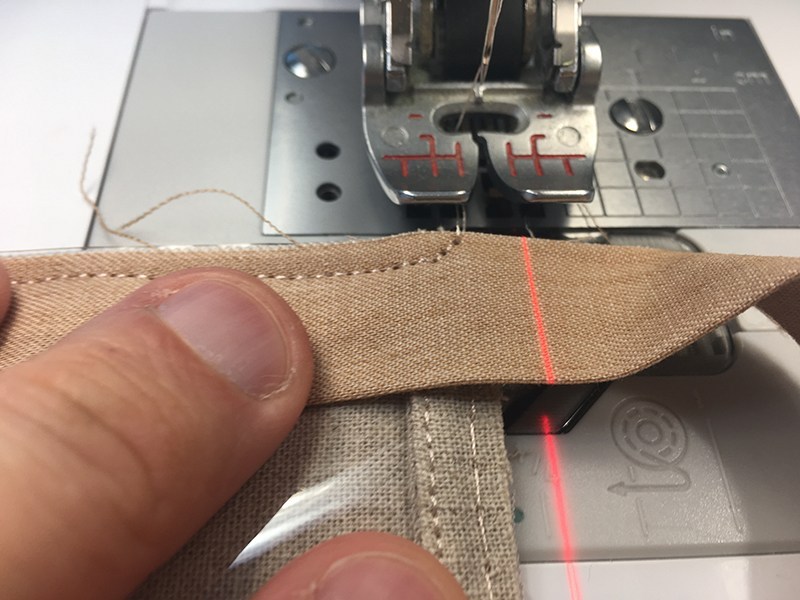

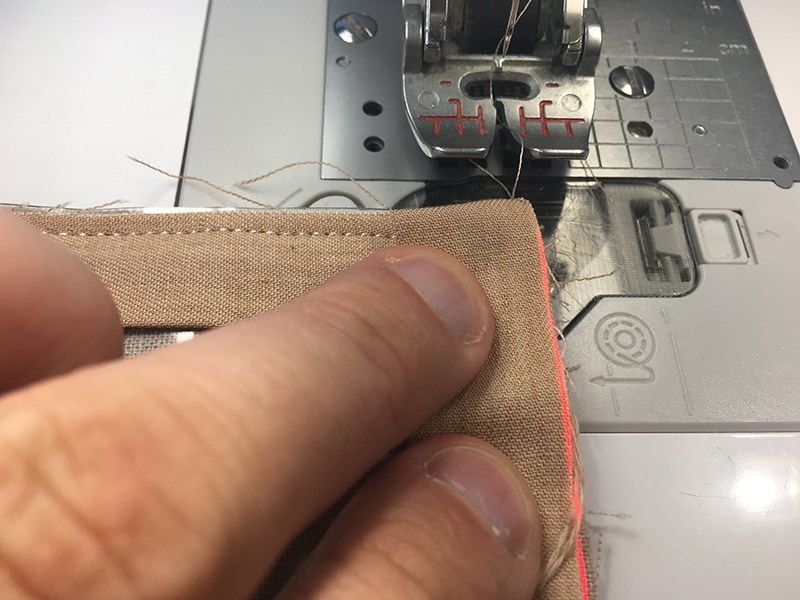

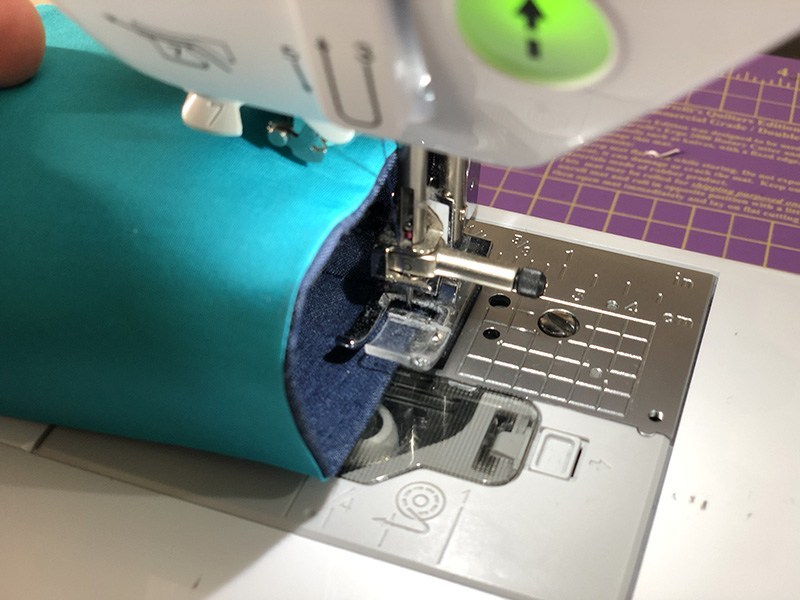

•t With right sides and raw edges together,

stitch the binding onto the denim with a 1⁄ 2″

seam allowance. Turn to the wrong side, tuck

the raw edge under to the stitching line, pin,

press and edgestitch in place (C).

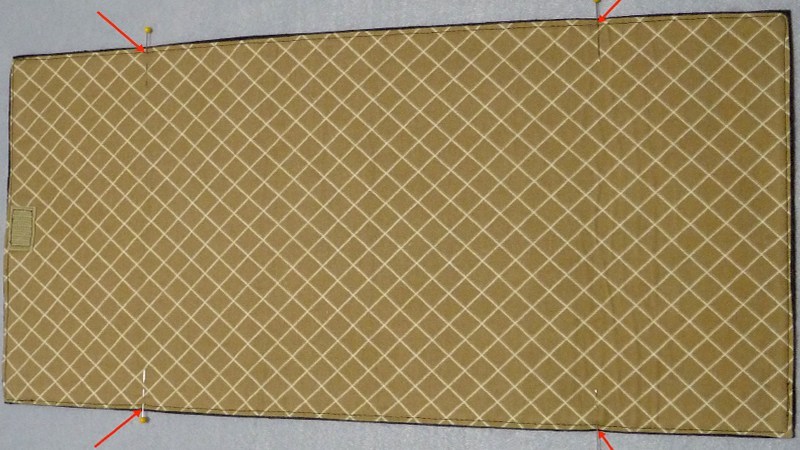

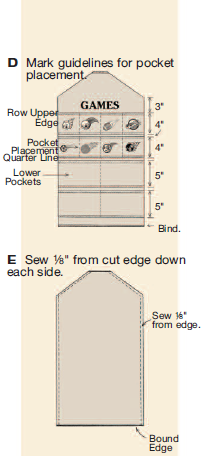

• Follow the diagram and mark guidelines for

pocket placement (D).

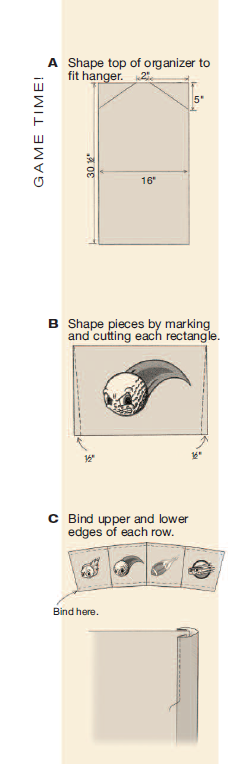

working with multiple motifs

• When embroidering multiple motifs for a grouping, select thread colors that will harmonize

as a complete unit.

• Choose a similar motif size and theme when stitching multiple motifs.

• Make minor adjustments to a motif’s size, if needed, to help it better harmonize with

other motifs.

• When sizing a motif up at the machine, the stitch count may or may not change

depending on your machine brand causing the stitches to be further apart. In this case,

use 30-weight embroidery thread to prevent the base fabric from showing through.

• Position the prepared rows along the

marked lines matching the quarter lines for

placement. Sew along the horizontal lines.

• Stitch-in-the-ditch on the seamlines to create

individual pockets.

• Bind the hanger opening upper and lower

edges (refer to D).

• Repeat to bind the backing fabric upper and

lower edges.

• With the panels wrong sides together, sew

1⁄ 8″ from the cut edge down each side as

shown (E). Leave the upper and lower bound

edges open for the hanger.

• Bind the sides, turning the binding raw ends

toward the organizer inside. Stitch to secure.

• Insert the hanger inside the organizer.

Enjoy this custom video game organizer from us. If you have any questions or comments please email us using the form HERE.